Carpet samples dry mop

Abstract

The objective for the team, Empire Today, was to find a way to add value to SCRAP Humboldt’s donated carpet samples. We created a carpet sample dry mop that would function as an effective dusting device of hardwood, linoleum, and tile flooring. It features 3D printing of a ball and socket joint that connects a handle with a head comprised of carpet samples. This design will help divert carpet samples from the waste stream. There were other designs and iterations that were considered, but the carpet sample dry mop proved to be the best solution to the problem.

Team Photo (left to right): Andrea Pedroza , Spencer Davis, Alex Simmions, and Shannon McHatton

Background

SCRAP Humboldt is a creative reuse center in Humboldt County, California. SCRAP Humboldt aims to take materials that can still be used to create new products. SCRAP teamed up with Cal Poly Humboldt students enrolled in Engr 215 Introduction to Design to promote sustainable living by challenging teams of to create projects that were aimed towards diverting usable materials from the waste stream. One of the materials in particular was carpet samples. From this project assignment the Carpet Sample Dry Mop was created.

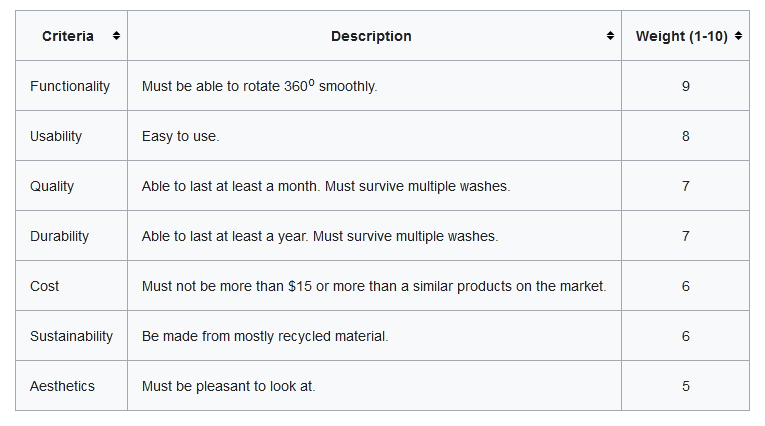

Problem statement and criteria

SCRAP Humboldt has an abundance of donated carpet samples, but no practical use for them. Team Empire Today thought to make a dry mop out the carpet samples. The table below shows the criteria that was important for the dry mop to have, its definition of the criteria, as well as the level of importance.

Description of final project

Our final product is a carpet sample dry mop. It consists of a wooden handle that is attached to our 3D printed ball and socket joint with a pin. This pin firmly connects the handle and the joint. The joint is fixed to a small wooden block with four small screws. The block is stapled to a piece of industrial carpet. A softer wool carpet sample is attached to the bottom of the mop with velcro. The velcro was superglued to the top and bottom edge of the industrial and wool carpet sample. This allowed for quick removal of the carpet head for cleaning.

Costs

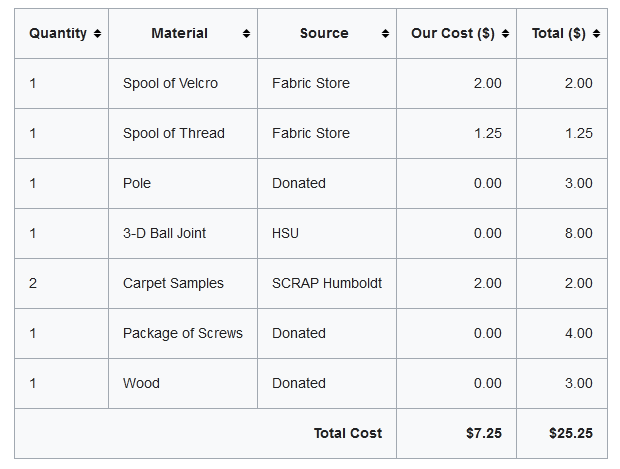

Material Costs

This table illustrates the market cost of the materials we used, and the cost that we actually paid.

Maintenance Costs

This table shows the cost to keep the mop in great working condition. Over time the velcro will become loose so you will need to rip off the old velcro and superglue the new velcro to the carpet. To clean the carpet, just detach the wool carpet sample from the industrial carpet sample and place it in the washer. After multiple washes you will notice that the carpet wears and starts to unravel. Once it becomes to unraveled to use you will need to replace it. The chart below gives the maintenance item and the cost to replace it.

Testing Results

During our testing we used the carpet sample dry mop on linoleum floors. The floor was dirty and had large pieces of trash, dirt, and dust. The carpet sample dry mop was able to easily clean up the mess on the floor. In addition it was able to navigate smoothly in tight spaces and pick up much of the dust and dirt. During the testing process it was found that the carpet sample dry mop didn’t work well when using dusting sprays, although it was able to pick up dust without a dusting spray.

Materials

- Old broom or mop stick (preferably wood)

- 1/4 in diameter bolt and nut (bolt needs to be 1-3/4 in long)

- O ring with OD = 1-7/16 in and ID = 1-5/16 in (wall = 1/16 in)

- 4 screws ( 3/16 in diameter and 3/4 in long)

- Wooden block (dimensions = 2-3/4 X 1-1/2 X 3/4)

- Staple gun and staples

- Carpet Samples (one with soft material for mop head and one with sturdy backing to attach head to the joint)

- Velcro (1 foot cut into 4 equal sections)

- Drill

- Super glue

- 3D printed ball and socket joint. (Joint: File:Ball and Socket Joint.stl) (Ball: File:Ball and Socket Joint Ball.stl)

How to build

Discussion and Next Steps

Our challenge was to add value to carpet samples that would normally just go into the waste stream. The carpet sample dry mop does that and so much more. The mop is great for its purpose, but there is always room to get better. To improve the sustainability of the mop, we could use recycled plastics for 3D printing instead of using the commonly used ABS plastic. This would make the mop almost 100% from recycled materials.

Update October 2016

The original carpet samples dry mop (made in 2013) is currently at SCRAP Humboldt. As reported by the current director, Mindy Hiley, the mop is used regularly for cleaning and maintenance at SCRAP Humboldt. Some of the blue paint on the wood pole is worn off because of use, and it has some minor scratches and dust around the mop area also because of regular use. On average the carpet samples are washed every two weeks, and exchange for a new one around every 4-5 months. The 3D printed ball & socket joint still work perfectly, and overall the mop is in great condition & still usable.

Scrap Humboldt, US

PROFILE

SCRAP Humboldt is “a project of SCRAP, a 501(c)(3) nonprofit organization. Our mission is to inspire creative reuse and environmentally sustainable behavior by providing educational programs and affordable materials to the community.”