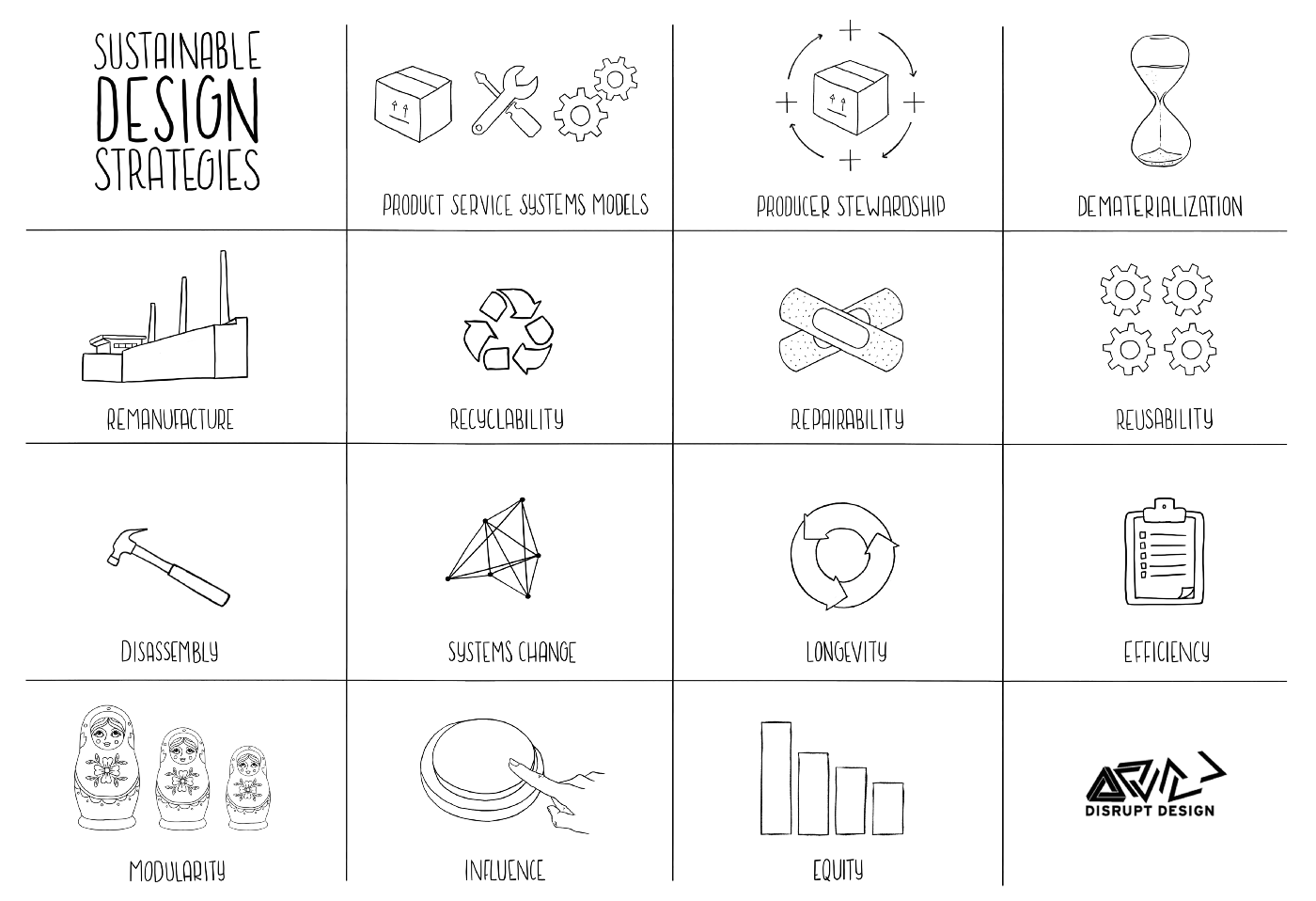

Quick Guide to Sustainable Design Strategies

Sustainable design is the approach to creating products and services that have considered the environmental, social, and economic impacts from the initial phase through to the end of life. EcoDesign is a core tool in the matrix of approaches that enables the Circular Economy.

There is a well-quoted statistic that says around 80% of the ecological impacts of a product are locked in at the design phase. If you look at the full life cycle of a product and the potential impacts it may have, be it in the manufacturing or at the end of life stage, the impacts are inadvertently decided and thus embedded in the product by the designers, at the design decision-making stage.

This makes some uncomfortable, but design and product development teams are responsible for the decisions that they make when contemplating, prototyping, and ultimately producing a product into existence. And thus, they are implicated in the environmental and social impacts that their creations have on the world. The design stage is a perfect and necessary opportunity to find unique and creative ways to get sustainable and circular goods and services out into the economy to replace the polluting and disposable ones that flood the market today. The challenge is which designers will pick up the call to action and start to change the status quo of an industry addicted to mass-produced, fast-moving, disposable goods?

For those that are ready to make positive change and be apart of the transition to a circular and sustainable economy by design, the good news is there is a well-established range of tools and techniques that a designer or product development decision-maker can employ to ensure that a created product is meeting its functional and market needs in ways that dramatically reduce negative impacts on people and the planet. These are known as ecodesign or sustainable design strategies, and whilst they have been around for a while, the demand for such considerations is even more prominent as the movement toward a sustainable, circular economy increases.

Sustainability, at its core, is simply about making sure that what we use and how we use it today, doesn’t have negative impacts on current and future generations’ ability to live prosperously on this planet. Its also about ensuring we are meeting our needs in socially just, environmentally positive and economically viable ways, so its very much a design challenge. Consumption is a major driver of unsustainability, and all consumer goods are designed in some way.

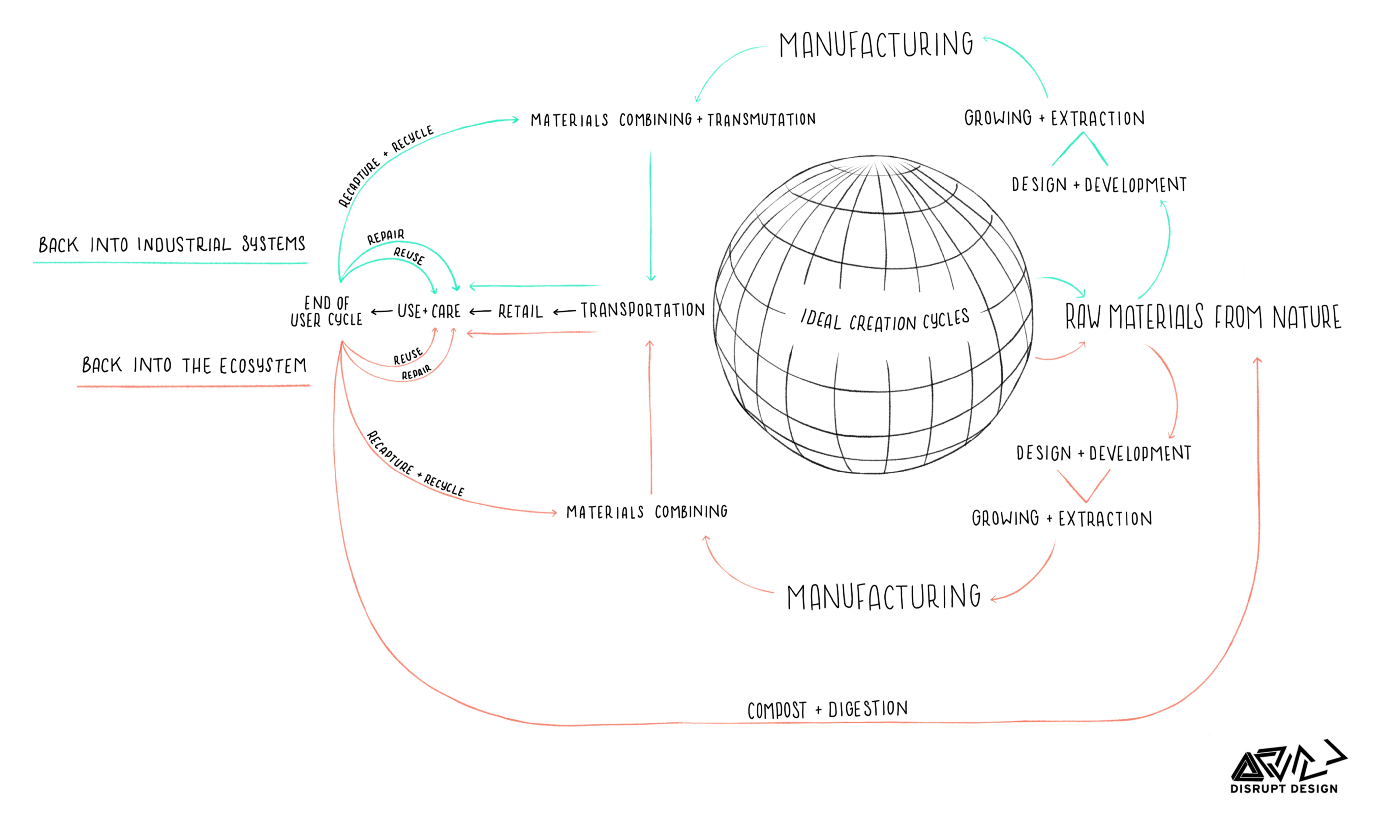

When sustainability is applied to design, it enlightens us to the impacts that the product will have across its full life cycle, enabling the creator to ensure that all efforts have been made to produce a product that fits within the system it will exist within in a sustainable way, that it offers a higher value than what was lost in its making, and that it does not intentionally break or be designed to be discarded when it is no longer useful. Provisions should have been made so that there are options for how to maximize its value across its full life cycle and keep materiality in a value flow. This is otherwise known now as the circular economy and the practice of enabling this is circular systems design.

Long before there was a Twitter hashtag devoted to all things sustainability, sustainable design pioneers like Buckminster Fuller and Victor Papanek were figuring out how to reduce the impact of produced goods and services through design. As the sustainability concept has evolved, so has the framework for the thinking and doing tools that we now can routinely integrate into our practices to help understand and design out impacts and design in higher value. I see sustainable design as one of the tools that we each need to employ in order to make things better, its the practical side of considering sustainability, connected to considerations around life cycle thinking, systems thinking, circular thinking and regenerative design. By understanding these approaches, a toolbox for change can be created by any practitioner to advance their ability to create incredible things that offer back more than they take. This should be the goal of any creative development.

The ecodesign strategy set for sustainable design includes techniques like Design for Disassembly, Design for Longevity, Design for Reusability, Design for Dematerialization, and Design for Modularity, among many other approaches that we will run through in this quick guide. Basically, the ecodesign strategy toolset helps us think through the way something will exist and how to design for value increases whilst also maintaining functionality, aesthetics, and practicality of products, systems, and services. It’s especially effective when applying materiality to any of the creative interventions you are pursuing in your changemaking practice, be it a designer or not. I have a free toolkit for redesigning products to be circular that also details all of these strategies and more.

For decades, much progressive experimentation and exploration of ecodesign, cleaner production, industrial ecology, product stewardship, life cycle thinking, and sustainable production and consumption has occurred, which all led up to the current framing of a new approach to humans meeting their needs in ways that don’t destroy the systems needed to sustain us. Right now the framing is around creating a sustainable, regenerative, and circular economy, whereby the things we create to meet our needs are designed to fit with the systems of the planet and maintain materials in benign or beneficial flows within the economy, which requires businesses to change the way they deliver value and consumers to adjust their expectations around hyper-consumerism. Central to this success is the design of goods and services and that’s where these strategies and designers’ creativity fit in.

There have been thousands of academic articles and business case studies on a multitude of different approaches to sustainable and ethical business practices, demonstrating the strong and clear need for systems-level change. Contributions from biomimicry, cradle to cradle, product service systems (PSS) models, eco-design strategies, life cycle assessment, eco-efficiency and the waste hierarchy all fit together to support this approach to sustainable design.

Circular Design Forum: Closing Keynote by Dr. Leyla Acaroglu from IDZ Berlin on Vimeo.

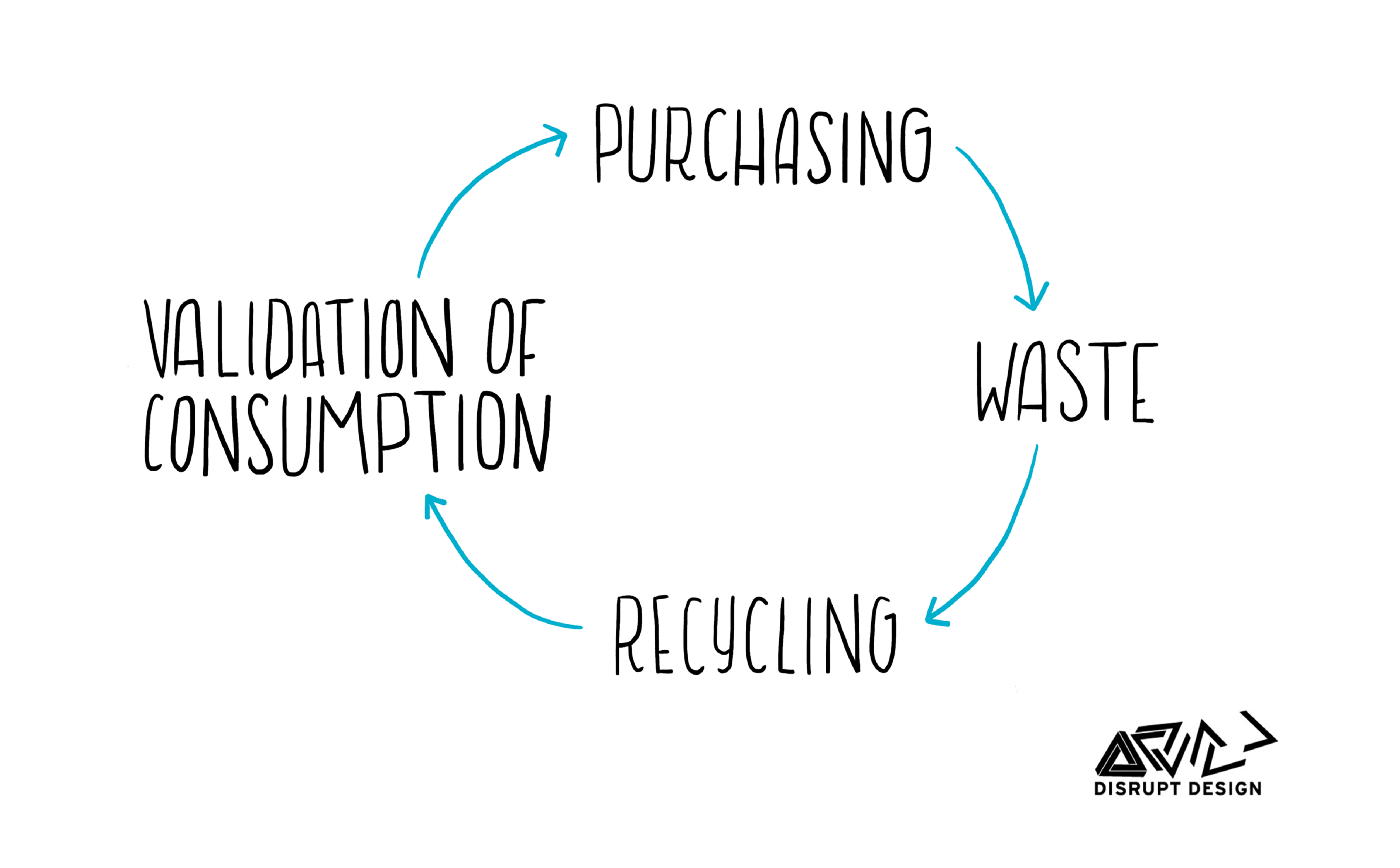

The Circular Economy

Within the last 20 or so years, we have really started to feel the negative impacts of what’s called the linear economy, where raw materials are extracted from nature, turned into usable goods, purchased and then quickly discarded usually due to poor design choices, inferior materials or trend changes (or the more insidious practice of planned obsolescence). Recently, there has been a great framing around the shift from linear to circular systems called The Circular Economy Framework, which combines a range of pre-existing theories and approaches. Moving to a circular economy (which embraces closed-loop and sustainable production systems) means that the end of life of products is considered at the start, and the entire life cycle impacts are designed to offer new opportunities, not wasteful outcomes.

Our interpretation of the value flows within the circular economy from the Circular Systems Design handbook

You may be wondering — especially if you aren’t a designer — how can we integrate this into a creative practice to make a positive change? Well, here’s the thing, the approaches to understanding and reducing the impacts of material processes are really important to reduce the use of global materials and the ecological impacts of our production and consumption choices. This is what the circular economy movement is seeking to achieve: a transformation in the way we meet our material needs.

On top of that, these approaches are very empowering for non-material decisions — you start to see the ways in which the world works and can apply this thinking to different problem sets. Sustainable design and production techniques allow for reducing the material impact by maximizing systems in service design — thus, providing sustainability during both production and consumption.

From our free educational project, The Circular Classroom. Find out more here

EcoDesign Strategies

These sustainable design strategies are best known as starting off with Victor Papanek in the 1970’s and have been contributed to over the years by many different people and approaches. This curated life of ‘design for x’ strategies takes into consideration the circular economy and how they relate to closing the loop and dramatically changing economic models.

In this list I have curated, I have also included a few “negative” design approaches at the end to remind you what not to do, and how easy it is to accidentally do the wrong thing right, rather than the right thing a little bit wrong.

In order to achieve circular and sustainable design, some, or many, of these design considerations need to be employed in combination throughout the design process in order to ensure that the outcome is not just a reinterpretation of the status quo, but something that actually challenges and changes the way we meet our needs.

These approaches are lenses you apply to the creative process in order to challenge and allow for the emergence of new ways to deliver functionality and value within the economy. There are also separate considerations of the circularization process outlined in the next section.

Product Service Systems (PSS) Models

One of the main ideas of the circular economy is moving from single-use products to products that fit within a beautifully designed and integrated closed-loop system which is enabled through this approach. Think of alternatives to purchasable products such as leasable items that exist as part of a company-owned system or services that enable reuse. Leasing a product out — rather than selling it directly — allows the company to manage the product across its entire life cycle, so it can be designed to easily fit back into a pre-designed recycling or re-manufacturer system, all whilst reducing waste.

By transitioning away from single end-consumer product design to these PSS models, the relationship shifts and the responsibility for the packaging and product itself is shared between the producer and the consumer. This incentivizes each agent to maintain the value of the product and to design it so that it’s long-lasting and durable. PSS requires the conceptualization of meeting functional needs within a closed system that the producer manages in order to minimize waste and maximize value gains after each cycling of the product. Many of the circular economy business models are either based on this concept or create services that enable the ownership of the product to be maintained by the company and leased to the customer. But it’s critical that this is done within a strong ethical framework and not used to manipulate or coerce people, as this could also easily be the outcome of a more explorative version of this design approach.

Product Stewardship

In a traditional linear system, producers of goods are not required to take responsibility of their products or packaging once they have sold the product into the market. Some companies offer limited warranties to guarantee a certain term of service, but many producers avoid being involved in the full life of what they create. This means that there are limited incentives for them to design products with closed-loop end of life options. In a circular economy, producers actively take responsibility for the full life of the things they create starting from the business model through to the design and end of life management of their products.

Product stewardship and extended producer responsibility are two strong initiatives that encourage companies to be more involved in the full life of what they produce in the world. There are several ways that this can occur; in a voluntary scenario, companies work to circularize their business models (such as a PSS model) or governments issue policies that require companies to take back, recapture, recycle or re-manufacture their products at the end of their usable life. For example, the European Union has many product stewardship policies in place to incentivize better product design and full life management such as the Ecodesign directive, WEEE, Product Stewardship and now the circular economy directives.

The key here is that the design of both the products and the business case is created to have full life-cycle responsibility and is managed as an integrated approach to product service delivery so that the product doesn’t get lost from the value system. Partnerships between organizations can enable a rapid introduction of product stewardship, such as a bottling company leasing the service of beverage containers to the drinks company. One key element of this is a take-back program, whereby the producing company offers to take back and reconfigure, repair, remanufacture or recycling the products they produced. This incentivizes them to design them to be easily fixed, upgraded or pulled apart for high-value material recycling.

Dematerialization

Reducing the overall size, weight and number of materials incorporated into a design is a simple way of keeping down the environmental impact. As a general rule, more materials result in greater impacts, so it’s important to use fewer types of materials and reduce the overall weight of the ones that you do use without compromising on the quality of the product.

You don’t want to dematerialize to the point where the life of the product is reduced or the value is perceived as being less; you want to find the balance between functional service delivery, longevity, value and optimal material use.

Modularity

Products that can be reconfigured in different ways to adapt to different spaces and uses have an increased ability to function well. Modularity can increase resale value and offer multiple options in one material form. Just like you can build anything with little Lego blocks, modularity as a sustainable design approach implicates the end owner in the design so they can reconfigure the product to fit their changing life needs.

As a design approach for non-physical outcomes, modularity enables creatives to consider how the things they create can be used in different configurations. This is all about making this adaptable to different scenarios and thus increase value over time. It’s important to ensure designs are durable enough to withstand being taken apart and reconfigured, as well as making it easy to do and the style timeless so it increases its duration of use. Modularity should also increase recycling and repairability by offering replacement parts and a service model.

Longevity

Longevity is about creating products that are aesthetically timeless, highly durable and will retain their value over time so people can resell them or pass them on. Products that last longer aren’t replaced as frequently and can be repaired or upgraded during their life as long as their style and functionality have durability as well.

Ensure that the materials you select enable a long life, and be sure to consider multiple use case scenarios such as repair options and resale encouragement.

Disassembly

Design for disassembly requires a product to be designed so that it can be very easily taken apart for recycling at the end of its life. How it is put together, the types of materials that are used and the connection methods all need to be designed to increase the speed and ease of taking it apart for repair, remanufacturing and recycling. Often the case with technology, the norm is to design products that lock the end owner out, discouraging any form of repairability during the use phase while also reducing the likelihood of recapturing the materials at the end of life.

This design strategy is particularly relevant to technology, requiring the design of the sub and primary components to be just as easily disassembled as it is to manufacture them. For maximum recapture, we need to reduce the number of different types of materials, the connection mechanisms, and the ease of extraction. This is a super critical strategy for monitoring technical materials inflow to reduce negative impacts at end of life.

Recyclability

Making a recyclable product goes beyond simply selecting a material that can be so. You have to consider the recyclability of all the materials, the way they are put together and the use case, along with the ease of recycling at end of life. Relying on something being “technically recyclable” as a sustainable design solution to your product is just lazy and often does not result in environmental benefits, as recycling is very much broken. So, you need to ensure that it is being designed to maximize the likelihood that it will be recaptured and recycled in the system it will exist within.

Assembly methods will impact how easily disassembled for recycling products will be. Also, make sure that there are systems in place so that the product can actually be recycled in the location it will end up! For it to be circular, the product has to fit within a closed-loop system, and recycling often is the least beneficial outcome since we lose materials and increase waste through this system.

Connected to disassembly is the ability to easily and cost-effectively recapture the material at end of life. Just making something recyclable does not guarantee that it will be recycled, as it’s often costly and time-consuming. Additionally, many technology items are shredded to get the valuable parts (like gold) instead of getting all the different parts back. What is crucial about this strategy is that it must be used in a system that has the appropriate and functioning recycling market, or a take-back and recapture system must be in place, as well as design features that maximize the behavioral outcomes of the end owners so that the product is actually reacquired and recycled. The Scandinavian bottle recycling system is a perfect example of this. Drink bottles are made of thick and durable materials that can be washed and re-manufactured, and the system is set up with an easy-to-use deposit program and financial incentive to maintain a high level of recapture.

Repairability

Repair is a fundamental aspect of the circular economy. Things wear out, break, get damaged, and need to be designed to allow for easy repair, upgrading, and fixability. Along with the extra parts and instructions on how to do this, we need systems that support, rather than discourage, repair in society. For example, many Apple products are intentionally designed to be difficult to repair, with patented screws and legal implications for opening products up.

Sweden recently opened the world’s first department store dedicated to repair, but any product producer can put mechanisms into place for ease of repair so that the owner has more autonomy over the product and will be encouraged to do so. The Fair Phone is a great example of this.

Reusability

Repair allows the end owner to maintain its value over time, or sell it more easily to then increase its lifespan. But there is also the option of designing so that the product can be reused in a different way from its intended original purpose, without much extra material or energy inputs. An example of this is a condiment jar designed to be used as a water glass.

There are many ways a product can serve a second or even third life after its core original purpose. This approach is useful when you have limited options for designing out disposability.

Re-manufacture

For this strategy, the producer takes into consideration how the parts or entire product can be re-manufactured into new usable goods in a closed-loop system; it’s critical to the technology sector but fits perfectly for many products.

Re-manufacturing is when a product is not completely disassembled and recycled or reused, but instead, some parts are designed to be reused and other parts recycled, depending on what wears out and what maintains its usefulness over time.

Efficiency

During the use phase, many products require constant inputs, such as energy, in the form of charging or water in the form of washing. When a product requires lifetime inputs, it’s called an “active product”, meaning it is constantly tapping into other active systems in order to achieve its function. That’s when design for efficiency comes in, designing to dramatically reduce the input requirements of the product during its use phase.

This will increase the environmental performance and also reduce wear of the product, increasing lifetime use. This approach can also be taken as an overarching one — design to maximize the efficiency of materials, processes, and human labor. As a general rule, “Weight equals impact,” and the more efficient you can be with materials, the lower the overall impact per product unit (this rule has many exceptions, as it is always related to what the alternatives are).

Influence

Things we use influence our lives. This is why social media applications are designed to act like slot machines with continuous scroll, and why airport security lines make you feel like a farm animal. The things we design in turn design us, and thus there is a huge scope for creating products, services, and systems that influence society in more positive ways.

There is still a lot of resistance to sustainability, often because it seems confusing. So, imagine how you can design things that give people an alternative experience to this mainstream perspective. Designing in positive feedback loops to the owner helps change behaviors, just as designing in less options to limit confusion can help direct the more preferable use.

Equity

Accidentally or intentionally, many goods are designed to reinforce stereotypes. Pink toys for girls, dainty watches for women, and chunky glasses for men are a few examples. Reinforcing stereotypes subtly maintains negative and inequitable status quos in society. There are entire labs dedicated to first researching an established trend, and then designing to reinforce it. Design for equity requires the reflection and disruption of the mainstream references that reinforce inequitable access to resources, be it based on gender or outdated stereotypes.

Oppression and inequality exist everywhere, from toilet seat designs to office buildings. Considering the potential impact of your designs on all sorts of humans is critical to creating things that are ethical and equitable. This also applies to the supply chain, ensuring that people along the full chain of materials and manufacturing are valued, paid fairly and respected.

Systems Change

Perhaps the most important of the design strategy tools is the ability to design interventions that actively shift the status quo of an unsustainable or inequitable system. The world is made up of systems, and everything we do will have an impact in some way of the systems around us. So instead of seeing your product as an individual unit, see it as an animated agent in a system, interacting with other agents and thus having impacts.

All systems are dynamic, constantly changing and interconnected. Materials come from nature, and everything we produce will have to return in some way. So, designing from a systems perspective with the objective of intervening will allow for more positively disruptive outcomes to the status quo (see my handbook on the Disruptive Design Method for more on this approach).

Other things to consider

- Where is the energy being sourced? Shift from fossil to renewables.

- What are the hidden impacts embedded within the supply chain? Remove embodied fossil fuel energy.

- How can you recover and put to good use all wasted resources across the supply chain? Look for industrial symbiosis or by-product reuse opportunities.

- How can you design in life extension on your products? Design repair and rescue options as a service for your products.

- Are there ways of partnering to create industrial symbiosis where your product’s by-products are used as raw materials for another process? Reduce waste to landfill by encouraging secondary industries to use industrial by-products.

- How can you design your product to be a service instead? Embrace full product stewardship.

- Do you need to produce a product to deliver the functional need? Look for alternative business models to deliver your customer’s functional desires.

- What is the energy mix in the manufacturing and use phase? The types of energy used will increase or decrease environmental impacts.

- Does a product need to exist or can we deliver value and function in a different format?

The UnSustainable Design Approaches!

There are many insidious techniques used by designers to manipulate and coerce consumers into behaviors and practices that are unsustainable and inequitable. Here are three types you should avoid! There are also many accidental actions that may have good intentions that result in greenwashing, so be careful not to invest more in marketing green credentials than in R&D to ensure your product truly is what you claim it to be.

Design for Obsolescence

Planned obsolescence is one of the critically negative ramifications of the GDP-fueled hyper-consumer economy. This is where things are designed to intentionally break, or the customer is locked out through designs that limit repair or software upgrades that slow down processes. This approach tries to constantly turn a profit by manipulating a usable good so its functionality is restricted or reduced and the customer is forced to constantly purchase new goods. It’s in everything from toothbrushes to technology. The habit has led to massive growth, but at the expense of durability and sustainability. How it is used as a positive strategy is when it is part of a well-designed closed-loop system that enables the product to naturally “die” at the right time so it can be reintegrated into the system it is designed within.

Design for Disposability

Designing for things to break is due to the cultural normalization of disposability as a result of increased use of disposability in the design of everyday goods. From coffee cups to technological items, it is a race to the bottom of our economy, where many reusable things have become hyper-disposable. Single-use items plague our oceans with plastic waste and increase the end cost for small businesses and everyday people, as the more addictive the cycle of disposability is, the more costly it becomes to deliver basic service offerings. I have written extensively about this; read more here.

Dark Patterning

A term coined by designer Harry Brignull, the idea of dark patterns are intentional tricks used by designers to manipulate and lure customers into taking actions they don’t necessarily make the choice to do or may otherwise not agree to. Dark patterning includes often exploiting cognitive weaknesses and biases to get people to do things like purchasing extra items they did not need when checking out online, or creating a sense of urgency to increase purchasing — leveraging single-click buy now for impulse buys, using particular colors to evoke emotions and sharing outright misleading information to increase purchases. This website has many great examples.

Much of this content is from my handbook on Circular Systems Design, and over at the UnSchool Online, I have a short course on sustainable design strategies and a more extensive one on sustainable design and production. You may also like to find out about the Disruptive Design Method that I created to support deeper design decisions that works to help solve complex problems. I also created the Design Play Cards which include all the eco-design strategies and fun challenges to solve.

UnSchool, US

PROFILE

The UnSchool of Disruptive Design

Pioneering the transformation to a sustainable & circular future by design. Disruptive Design Method & UnSchool

Disrupt Design is a New York based creative enterprize that uses design as a catalyst for creating positive social change. They produce activated experiences, toolkits, games, fellowship programs and brain-activating adventures. The use design as a catalyst for creative problem solving and sociology as a foundation for exploring and understanding the world.

Main Research Source

- Quick Guide to Sustainable Design Strategies - Leyla Acaroglu - Medium(27/05/2020)

- Circular Design Forum: Closing Keynote by Dr. Leyla Acaroglu - Vimeo(2018)

- Module 1: Moving from the linear to the circular economy - Circular Classroom - youtube(16/09/2018)

- Module 3: Design and creativity - Circular Classroom - youtube(16/08/2018)