Bottles used for storing carbonated water and soft drinks, has an uneven bottom for stability reasons. The technology was developed and patented by Lithuanian Domas Adomaitis in 1971. The indentations can be viewed as a “petaloid”, because it is shaped like a flower with petals.

Preforms (uninflated bottles) are now also used as robust and unique containers themselves; besides novelty candy, some Red Cross chapters distribute them as part of the Vial of Life program to homeowners to store medical history for emergency responders.

Recycling

Recycling

Plastic bottles are recycled by melting. The plastic is sorted by type, washed to remove contaminants and shredded into flakes. Finally, the flakes are melted into smalled spheres called pellets, about the size of a grain of rice. The pellets are then melted before being turned into new bottles.

Plastic (in the UK) is sorted using NIR (near infrared) technology. An infrared beam is shone onto the piece of plastic, which is then identified based on the wavelength that is reflected. Each plastic resin has a unique wavelength signature. Once the automated equipment has detected the plastic type, air jets blow the plastic into different areas, thereby sorting it. Once shredded, it then enters a Sink-float tank for density separation – high density material including PET drink bottles will sink, and low density material such as the bottle wraps and lids (made of a harder type of plastic #5 Polypropylene) will float.

Cap confusion

In some countries (such as the UK) the advise is to wash the bottle, let the bottle dry and put the cap back on. Plastic recyclers separate the lid from the bottle as above.

In other countries (such as some states in the US) they specifically say don’t put the cap in the recycling bin.

Best not to put the lids in separately. In countries that sort using a MRF (Materials Recovery Facility) it is based around item size, with small items literally and metaphorically falling though the cracks. This means lids can (and are likely to) get missed by the sorting and recycling process, as they can fall down the various gaps or off the numerous conveyor belts. A good rule of thumb is that recycling is easier with items larger than a tennis ball.

The upshot is that you have to find out what the recyclers in your area request – is seems to be common that this information is not simply stated on recycling bins.

A recent EU directive called for PET bottles to contain at least 30% recycled content by 2030.

Recent research found that drinks bottled using recycled Polyethylene Terephthalate (PET) can contained higher concentrations of chemicals than those bottled using new PET, which suggests that problems with the recycling process may be causing contamination. They are calling for more careful recycling methods to remove the potentially harmful chemicals.

Repurpose

Repurpose

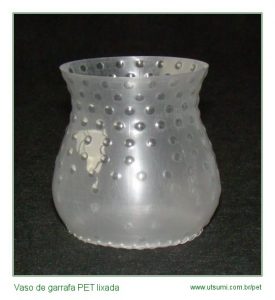

PET bottles are also repurposed for various uses, including for use in solar water disinfection in developing nations, in which empty PET bottles are filled with water and left in the sun to allow disinfection by ultraviolet radiation. PET is useful for this purpose because many other materials (including window glass) that are transparent to visible light are opaque to ultraviolet radiation

Reduce

Reduce

As ever though, the ultimate solution to the problem is for society to begin an end to the use of PET altogether.

“We all have a responsibility to bear. We need to start thinking about how to prevent the use of PET bottles in our households by investing, for example, in water filters, or large water containers and learning how to dispose of our plastic waste properly… If we reduce our consumption of PET then we will drive change further up the system. Less demand equals less production in the first place.”

Dr Eleni Iacovidou, a lecturer from Brunel’s centre for pollution research and policy

Warning

Warning

PET is known for being the source of a number of potential chemical contaminants, including endocrine disruptors such as Bisphenol A, which can cause reproductive disorders, cardiovascular problems and cancer, among other ill effects.

Properties

Properties

PET provides very good alcohol and essential oil barrier properties, generally good chemical resistance (although acetones and ketones will attack PET), and a high degree of impact resistance and tensile strength. The orienting process serves to improve gas and moisture barrier properties and impact strength.

- not resistant at high temperature

- maximum temperature is 200 °F (93 °C).

Sources

Recycling

Recycling Repurpose

Repurpose Reduce

Reduce Warning

Warning Properties

Properties