Plastic comes from the Latin ‘plasticus’, and as an adjective means ‘easily shaped or moulded’. Plastics are polymers, chains of repeating molecules linked together. Due to this structure, most plastic names start with the word ‘poly’ meaning ‘many or much’.

“Planet or Plastic?“, against the abuse of this material, this short video was also created that summarizes in a few minutes the whole history of plastic and its uses in the world. From the beginning, when the only source was plant, with the extraction of rubber from trees, the invention of industrial polymers, extracted from fossil fuels and then refined. The film ends with a series of suggestions on how to reduce the use of plastic, without packaging and using alternative materials.

Plastic manufacturing involves chemically joining single molecules, called monomers, together, which is usually started by distilling crude oil in a refinery. Crude oil will separate into components called fractions, which are different sized chains of hydrogen and carbon (hydrocarbons). One of these fractions is ‘naptha’, which is a building block of plastic. Naptha is ‘cracked’ into ethylene or propylene. Using heat and a catalyst, ethylene joins to form polyethylene, and propylene joins to form polypropylene. Most plastics we use are derived from these two polymers.

Although plastic comes in many forms, it can usually be classified as either rigid or flexible. Rigid plastic is strong, like a bottle, tray or yoghurt pot. Flexible plastic includes crisp packets, plastic bags or anything you can scrunch up.

Recycling

Recycling

Plastic is a by product of the oil industry, which explains its relatively low recycling rates; often, it is cheaper to buy new plastic than it is to recycle it. Its lightweight nature and multiple forms make it the most complex and prolific material in our product supply chains. At the moment MRFs only look for rigid plastics, as these are easier to recycle, although new technologies to recycle flexibles are being developed.

In countries such as the UK, plastic is sorted using NIR (near infrared) technology. An infrared beam is shone onto the piece of plastic, which is then identified based on the wavelength that is reflected. Each plastic resin has a unique wavelength signature. Once the automated equipment has detected the plastic type, air jets blow the plastic into different areas, thereby sorting it. The infrared light will not distinguish colour, so once the plastic has been sorted by type, cameras can be used to separate the different colours. Black plastic has often been dubbed ‘unrecyclable’ because it absorbs the infrared light and therefore does not generate a signature.

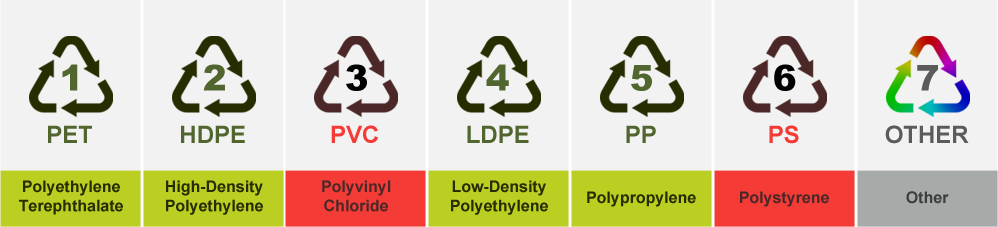

The Resin Identification Code (RIC)

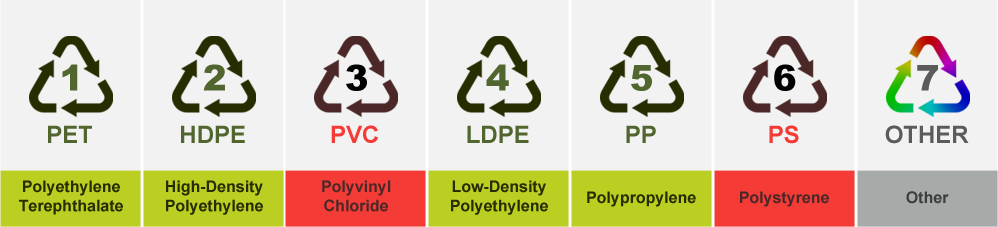

The system of identifying plastics by numbers was born in America in 1988 and designed to promote the consistent recycling of post-consumer plastic. The sorting of plastics was key to their recycling, and this code made the job easier.

The numbers range from 1 to 7 and indicate the type of plastic you have. They are useful when buying products as different numbers have differing levels of recyclability: some of them are definitely more economical to recycle than others.

The names of the plastics originate from the chemicals involved in the production of plastic. Fortunately they are known by their initials which are far easier to remember.

Plastic Resin Identification Codes

Image: You may see a variety of colour coded Resin Identification Codes but the colours have no recognised significance. Here red indicates those plastic types with more environmental concerns with regards to product manufacture use and recycling

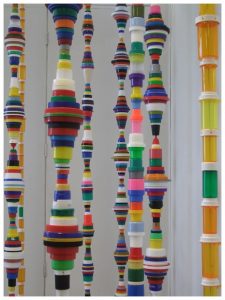

Art

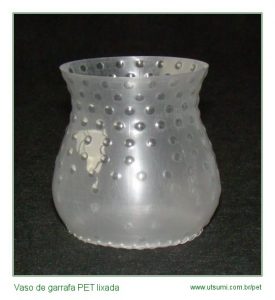

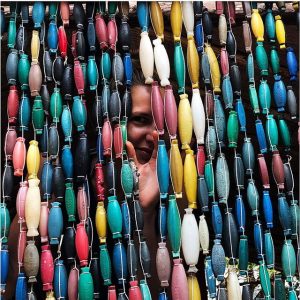

Generally, plastic has had a bad reputation, as it is the material that symbolises the petrochemical industry more than any other. However, the long-lasting nature of plastic, which makes it an enemy of many life forms, also makes it an abundant resource for re- and upcycling. Pictures of walls, houses, and smaller construction parts made of discarded bottles, have gone around the world. And numerous products are being developed today, where the plastic bottle is the main ingredient in upcycled clothing. With

the breakthrough of the 3D printer, we can fairly easily make sculptures out of upcycled plastic waste. But even without 3D printers, it is fairly easy to turn discarded plastic into art.

Sources

Recycling

Recycling